Lexus is the luxury vehicle division of the Japanese automaker Toyota. The Lexus brand is marketed in more than 90 countries and territories worldwide and is Japan’s largest-selling make of premium cars. It has ranked among the 10 largest Japanese global brands in market value.

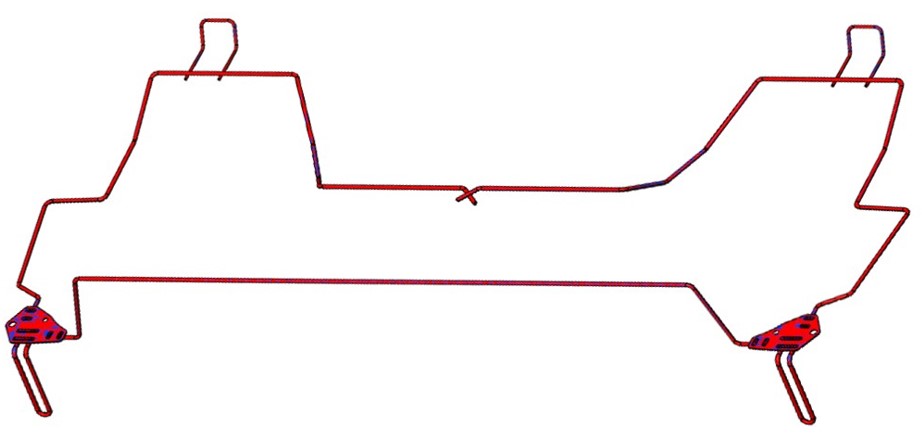

Guelph Manufacturing Group is a proud leading North American automotive seating supplier for Toyota Lexus and is manufacturing over 300K Rear Seat Armrest Frame Assemblies and Rear Seat Cushion Wireframes for the Lexus SUV per year. The main processes Guelph uses to manufacture the Rear Seat Armrest Assembly and Rear Seat Cushion Wire Frame for Toyota’s luxury vehicle produced by our Tier 1 automotive seating customer, Toyota Motor Corporation, is Wire and Tube Bending, Stamping, MIG and Resistance Welding.

Guelph Manufacturing Group specializes in wire, rod and tube manufacturing. We can straighten, cut and form wire or rod up to 1/2”. Guelph Manufacturing process includes flattening, hole piercing & punching, as well as tube swaging & chamfering, tube notch broaching, and stamped rolled formed notch. Guelph can tube bend diameters up to 1.5”. We can tube Seam find, laser 3D bar code or QR code etching or marking, as well as Transfer Die tube bending all in-house.

Guelph can produce high quality automotive seating metal stamped parts using 100 to 1600-ton metal stamping presses in our IAFT 16949:2016 and ISO 14001:2015 certified automotive seat manufacturing plants located in Ontario, Canada.

MIG welding metal assembly solutions include Automated CNC Robotic welding as well as Cold Metal Transfer welding (CMT) creating clean, quality welds because it is 99% less weld spatter vs. conventional MIG welding. Not only is it ideal for mechanical assemblies, it increases robot travel speed and decreases the need for fixture maintenance.

Our resistance welding options consists of Automated CNC or Robotic welding. Finally, in Spot welding, Guelph utilizes both Manual and Automated or dedicated weld cell and flexible robotic weld cell for high and low volume applications.

For just under 60 years, Guelph Manufacturing Group continues to be committed to producing high quality automotive seating parts and assemblies and has been exceeding our customer’s expectations giving value added results they depend on. Not only is Guelph proud to be an automotive seating supplier for Toyota Lexus, we are proud of being a leading North American automotive seating manufacturer and supplier of metal stampings, assemblies, head restraints and armrest inserts, formed wire, and other components for the automotive industry.

Please contact us and learn more about our quality products and industry-leading services you can depend on. Let us be your next leading North American automotive seating manufacturer and supplier partner for your next project.