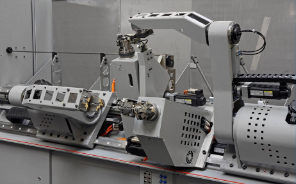

At Guelph Manufacturing Group, we are continuously looking to improve our wire bending processes and capabilities. We are pleased to announce the arrival of our latest Dual Head CNC Wire Bender.

The state of the art Dual Head Wire Bender features: two completely separate wire bending heads powered by new and improved variable speed dynamic drives, easy to use rotary wire straightener, and new software which cuts down on coil change time.

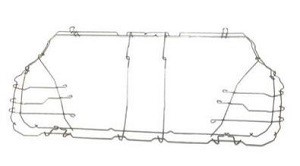

The CNC wire bending software calculates the speed and momentum of the “wire” as it is being formed. With wire speeds automatically being adjusted, wire shaking is minimized and cycle time and accuracy of the final wire product improves. Our new Dual Head CNC Wire Bender increases wire length capability, improves quality consistency, allows faster proto types and pre-production turnaround, and reduces tooling costs.

Having two wire bend heads completely separate from each other adds valuable flexibility allowing us to produce bent wires that are not symmetrical without the inefficiency of leaving one of the bend heads idle.

Guelph Manufacturing Group, located in Ontario, Canada invests in new technology to remain a viable and competitive automotive seating supplier. Our Wire Bending Department in Guelph, Ontario has increased capacity and capability with this investment.

For over 57 years, Guelph Manufacturing Group has been producing complex metal assemblies for our automotive seating customers. We are proud of our Made in Canada heritage. Guelph serves the automotive and industrial markets throughout Canada, United States and Mexico.

Contact Guelph Manufacturing Group for your next wire bending project.