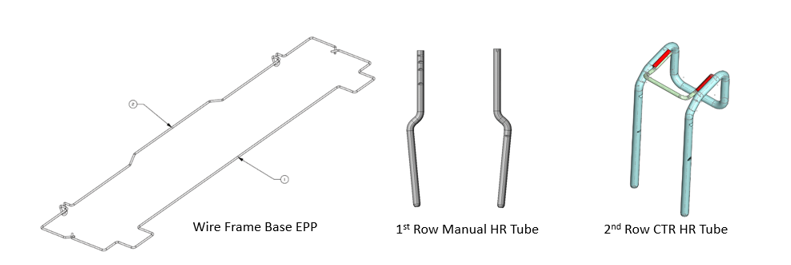

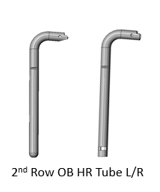

Guelph Manufacturing Group is proudly supplying head rest tubes and wire seat frame base for the brand new Grand Wagoneer. The Grand Wagoneer Full Size SUV now competes against the likes of the Lincoln Navigator, Cadillac Escalade, GMG Yukon Denali, and Chevy Suburban. The Grand Wagoneer offers seating for up to eight passengers and Guelph has the 1st and 2nd rows head restraint tubes for both manual and power head restraint armatures or stays.

Guelph Manufacturing Group utilizes CNC tube & wire bending, as well as MIG and resistance welding when making our head restraint and wire frame base. The wire seat cushion frame assemblies include:

- CNC wire formed seat cushions

- Welded seat bolster assemblies – Manual, Automated, Robotic, Resistance & MIG

- Automated assembly of high volume wire seat cushion frames

- Flexible robotic weld cells of rear wire seat cushions

Our seat manufacturing is located in Ontario Canada. Guelph Manufacturing Group is a leader in the automotive metal wire, rod & tube bending for automotive seat assemblies. Assembly services are provided to our customers across Canada, Mexico, and the U.S. We specialize in wire, rod and tube forming, at the highest quality and delivery standards. We routinely straighten, cut and form wire or rod up to ½” (12.7mm) and tube bending diameters up to 1.5” all in-house. With dependability and quality service expected by all our customers, Guelph can be your custom metal bending supplier.

You will want to use Guelph’s tube and wire bending for the following reasons:

- CNC wire and tube bending with fast and flexible lower cost tooling

- In die rod and tube bending including transfer die tube bending for high volume tube bending application

- We always recommend purpose built dedicated benders as well as our automated tube and rod bender manufacturing cells for your higher volume projects

Additional tube, rod and wire bending capabilities offered by Guelph Manufacturing include:

- Tube flattening, hole piercing and punching

- Automated tube end treatments include tube swaging and chamfering

- Seamless tube notch broaching and stamped rolled formed notch

- Accurate seam finding, as well as part etching & marking including 3D bar coding

- Coating options include chrome or zinc plating, as well as Ecoat and Acoat finishes through our supply partners