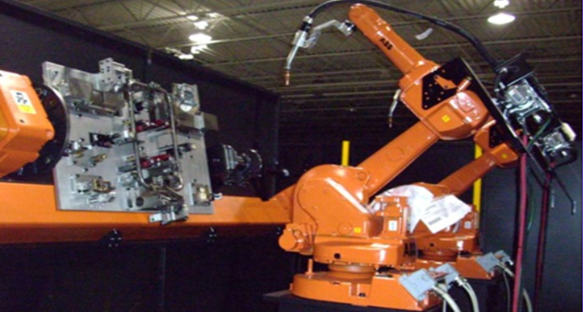

Experience the next level of welded assembly projects with Guelph Manufacturing’s advanced contract manufacturing capabilities in the automotive sector. Our seasoned team specializes in a wide array of welding services and non-welding fastening solutions, ensuring superior quality and efficiency.

Welding Services:

- MIG Welding: Manual, Automated, and Robotic

- Spot Welding & Resistance: Manual, Automated, or Dedicated Weld Cell for high and low volume applications

Non-Welding Fastening Solutions:

- Conventional nut and bolt assembly

- Spin riveting

- Staking

- Bushing insertion

- Crimping: Manual, Automated, or Robotic methods

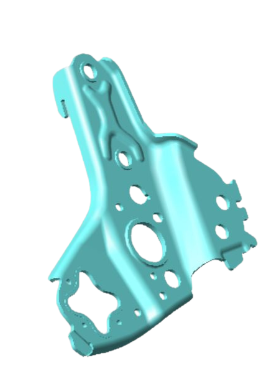

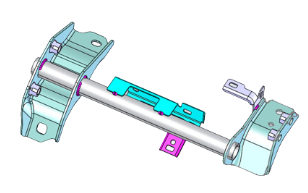

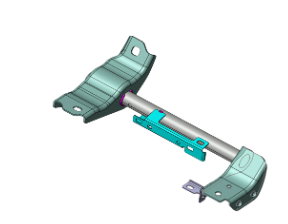

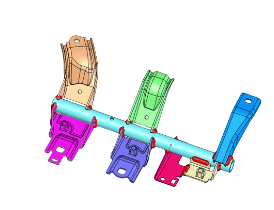

Guelph Manufacturing Group boasts a rich history as a trusted contract manufacturer for leading Tier 1 and Tier 2 automotive seating companies across North America, including Ford, Stellantis, GM, Honda, Toyota, and Hyundai. Our expertise spans a range of automotive assemblies and sub-assemblies, such as automotive seat riser assemblies, cross bar beams, ISO fix assemblies, tube seat riser assemblies, and wire and tube formed assemblies.

By partnering with Guelph Manufacturing Group for contract manufacturing needs, companies can leverage our specialized facilities without the need to allocate valuable in-house resources, space, or capital. Our services not only reduce labor costs but also alleviate the production burden, opening up more opportunities for companies to focus on core activities.

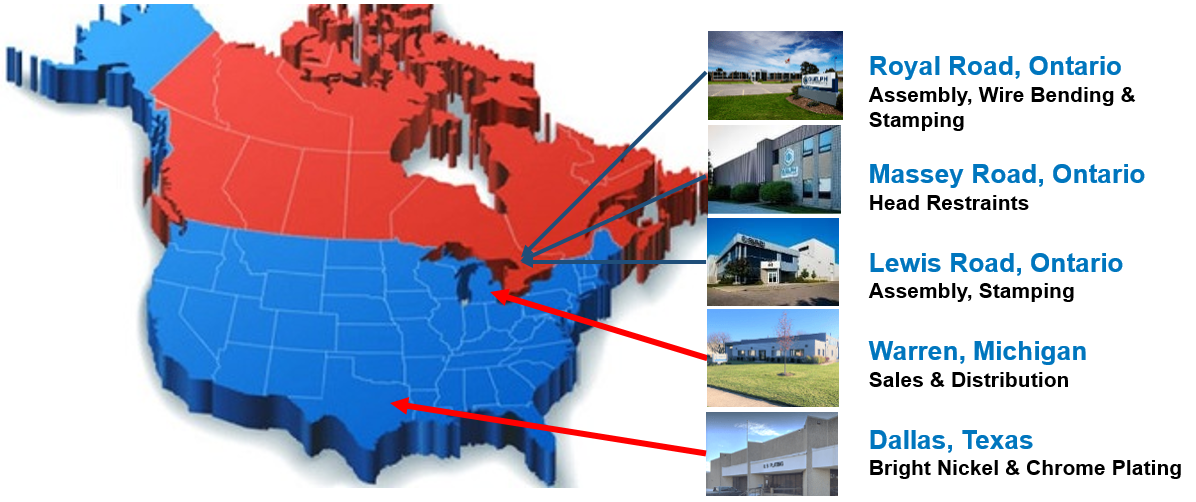

With three facilities strategically located in Ontario, Canada, and warehouse facilities in key locations like Warren, Michigan; and Irving, Texas, Guelph Manufacturing Group is well-equipped to cater to the complex needs of the automotive industry. Experience efficiency, quality, and reliability like never before with our advanced contract manufacturing solutions.