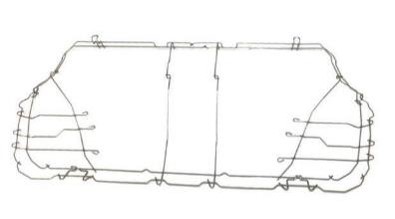

Guelph Manufacturing Group specializes in the production of precision formed wire for automotive and industrial uses, offering a wide range of wire bending options. Our primary focus lies in catering to the specific needs of the automotive industry. To meet varying volume and cost requirements of our customers, we employ advanced wire bending tooling such as CNC Benders and Dedicated Benders.

Leveraging our state-of-the-art wire bending CNC technology and automated bending and forming processes, we possess the capability to straighten, cut, and shape steel wire/rod up to a diameter of 5/8″ (16mm), ensuring we meet the precise specifications of our clients. With over 58 years of experience in the wire bending business, we have developed valuable expertise through our collaborations with automotive seating customers. Today, Guelph Manufacturing Group utilizes modern CNC Wire Bender equipment, providing us with unparalleled flexibility in programming and design.

To produce intricate forms and wire shapes, we rely on five critical components: coil feeder, straightener, chamfering, bending head, and cutting mechanisms. Our core competencies encompass tube bending, rod and wire forming, as well as stamping and assemblies. With three manufacturing plants at our disposal, we offer process options that cater to both low-volume production and larger quantities exceeding 250,000 units.

Guelph Manufacturing Group remains committed to delivering high-quality wire forming solutions for the automotive sector. Through our extensive experience, advanced technology, and diverse manufacturing capabilities, we strive to meet the evolving demands of our valued customers.